If you’ve spent any time in South Florida, you already know our climate doesn’t play around. One season it’s blazing sun and humidity, the next it’s hurricane prep and watching the radar. As a builder working in this region for over a decade, I’ve seen the difference between homes built with standard products and homes built with truly high-performance materials. The gap shows up in everything: comfort, maintenance, insurance, and how well a property weathers a serious storm.

In this guide, we’ll unpack high-performance building materials South Florida climate realities in plain language, and show you materials for wind humidity salt air South Florida homes that actually stand up to the environment. By the end, you’ll understand Why High-Performance Materials Matter in South Florida’s Climate (Wind, Humidity, Salt Air and how to make smarter choices for your custom or luxury home.

Understanding South Florida’s Challenging Coastal Environment

Extreme Weather & Wind Conditions

Hurricane-force winds and flying debris risks

South Florida homes don’t just see “a bit of wind.” We’re talking hurricane-force gusts, pressure changes, and flying debris that can hit like a projectile. That’s why the best construction materials for coastal Florida durability are tested under impact conditions that simulate real storm events. If your structure and openings aren’t designed for this, you’re essentially asking the home to do a job it was never trained for.

Strict wind-load design standards in Florida Building Code

The Florida Building Code has some of the strictest wind-load requirements in the country. Your roof, windows, doors, and structural system must be engineered for uplift, lateral loads, and impact. High-performance materials make it easier to meet (and exceed) these standards without cobbling together patchwork solutions during construction.

High Humidity & Moisture Exposure

Mold, mildew, and indoor air-quality challenges

Year-round humidity is part of the South Florida story. If you use the wrong materials inside walls and ceilings, you invite mold, mildew, and all the air-quality problems that follow. Moisture-resistant materials, proper vapor barriers, and smart insulation choices are non-negotiable if you want a healthy home.

Impact on structural materials, insulation, and finishes

Humidity doesn’t just make you feel sticky—it affects how wood swells, how finishes cure, and how long insulation keeps performing. Building materials that withstand humidity and salt air Florida-wide are designed to limit warping, rot, and breakdown in these conditions.

Salt Air & Corrosion Risks

Accelerated corrosion of metal components

Live near the ocean or Intracoastal and the salt air becomes a constant, invisible force working against your home. Standard metal fasteners, railings, and hardware can rust or pit in a fraction of the time you’d see inland. That’s why high-performance materials luxury homes South Florida rely on are often “marine-grade” by default.

Long-term deterioration of exterior surfaces and hardware

Salt, UV exposure, and wind-driven rain all accelerate wear on paint, stucco, deck surfaces, and even outdoor kitchens. If you don’t think about corrosion and coating performance early, you pay for it in constant touch-ups and replacements later.

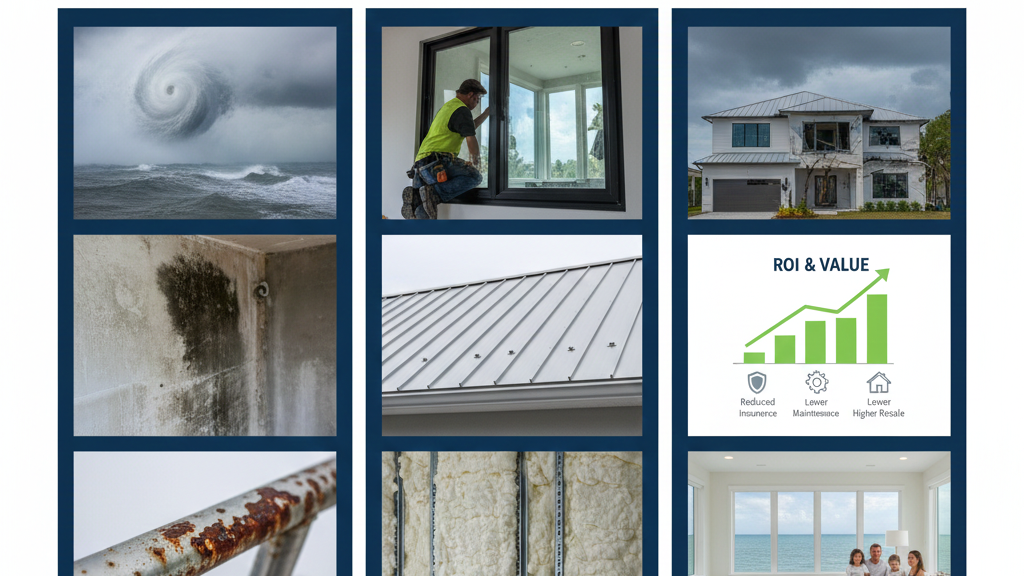

Why High-Performance Materials Are Essential

Durability & Long-Term Structural Integrity

High-performance materials withstand harsh climate cycles

In South Florida, your home may experience intense sun, sideways rain, high humidity, salt spray, and strong winds—all in the same week. Materials with strong UV resistance, moisture tolerance, and structural stability simply last longer in that environment.

Reduce maintenance, repairs, and replacement costs

Yes, premium materials tend to cost more up front. But they also save you from re-roofing too early, constantly repainting rusty railings, replacing swollen doors, or remediating interior moisture issues. Over time, the math favors quality.

Storm & Wind Resilience

Materials designed for hurricane resistance (impact rating, wind-load testing)

When we specify climate-resistant materials for Palm Beach homes, we’re looking at impact ratings, pressure testing, and uplift performance—especially for roofs and openings. These systems are designed to work together during a storm, not just look good on blue-sky days.

Improved performance during major storm events

Homes built with high-performance systems hold up better in extreme weather. Roofs stay attached, windows stay intact, and water intrusion is minimized. That’s not just about saving the structure; it’s about protecting everything and everyone inside.

Protecting Indoor Health & Comfort

Moisture-resistant materials prevent mold and allergen buildup

Good material choices behind the walls—like mold-resistant drywall and the right insulation—help keep humidity and condensation in check. That reduces the chance of hidden mold colonies and improves indoor air quality for everyone living in the home.

Enhance energy efficiency and climate consistency

High-performance windows, insulation, and air barriers help your HVAC system work less and your home feel more consistent. You’re not fighting hot spots, cold corners, or that “damp” feel on the muggiest days.

Key High-Performance Materials for South Florida Homes

1. Concrete & Reinforced Structural Systems

Steel-reinforced concrete block (CMU), ICF, poured concrete

For structural walls, concrete block (CMU), poured-in-place concrete, and ICF (insulated concrete forms) are common choices for high-performance building materials South Florida climate demands. They offer strength, mass, and resistance to rot and pests.

Superior resistance to wind, moisture, and pests

Compared to light wood framing, reinforced concrete offers greater resistance to uplift, lateral wind loads, and moisture intrusion. Termites and rot aren’t happy with concrete either, which is a big bonus in our environment.

Reduced long-term maintenance compared to wood framing

Properly detailed concrete structures tend to require less structural maintenance over time. You still need to care for finishes and waterproofing, but the bones are solid.

2. Impact-Resistant Windows & Doors

Laminated glass, tested to withstand airborne debris

Impact-rated windows and doors are a cornerstone of materials for wind humidity salt air South Florida homes. Laminated glass is designed to stay in place even when cracked, helping keep the building envelope intact during storms.

Corrosion-resistant frames (aluminum, fiberglass, composite)

Frames should be engineered for coastal use—often powder-coated aluminum, fiberglass, or composite materials designed to resist pitting and corrosion.

Energy-saving coatings for UV and heat control

Low-E coatings and selective tints reduce heat gain and UV damage to interiors while still letting in natural light. That combination is especially important in luxury homes with large glass areas.

3. Roofing Materials Built for Coastal Durability

Metal roofing, concrete tile, sealed deck systems

Metal roofs and concrete tile roofs, installed over properly sealed decks, are among the best construction materials for coastal Florida durability. They’re engineered for high wind speeds and long-term exposure.

Corrosion-resistant fasteners and attachment systems

Even the best roof covering fails if the fasteners aren’t right. Stainless or highly corrosion-resistant fasteners and clips help keep your roof in place under uplift forces and salt exposure.

Anti-moisture membranes for long-term protection

Self-adhered membranes, underlayments, and careful flashing details help keep water out—even when wind drives rain under tiles or panels.

4. High-Performance Exterior Finishes

Acrylic stucco, elastomeric paint, marine-grade coatings

Acrylic stucco and high-quality elastomeric paints stretch and move with the building, reducing cracking and water infiltration. On exposed metal, marine-grade coatings are worth their weight in gold.

Fiber cement, stone veneers, or composite sidings

Fiber cement and advanced composites resist rot, insects, and many of the issues that plague traditional wood siding in humid, coastal environments.

UV-resistant sealants and waterproofing barriers

Sealants and waterproof membranes are the unsung heroes behind many finishes. In South Florida, they must be UV-stable, flexible, and rated for long-term exposure to moisture.

5. Marine-Grade Metals & Hardware

Stainless steel grades 316/304, galvanized steel, powder-coated aluminum

For railings, balconies, outdoor kitchens, and coastal exterior elements, 316 stainless, high-grade galvanizing, or quality powder-coated aluminum go a long way toward preventing corrosion.

Prevent rusting in salt-air environments

Choosing the correct metal and finish is key. Get this wrong and you’ll be repainting, replacing, or grinding rust far more often than you’d like.

Required for railings, hinges, decks, outdoor kitchens

Anywhere metal meets the outdoors—hinges, screws, brackets, handles, cabinet hardware—should be specified with salt air in mind.

6. Moisture-Resistant Insulation & Interior Materials

Closed-cell spray foam, mineral wool, rigid insulation boards

Closed-cell foam and certain rigid boards offer excellent moisture resistance and air sealing. Mineral wool is another option that maintains performance even if exposed to some moisture.

Mold-resistant drywall, coatings, and vapor barriers

Using mold-resistant drywall (especially in baths, laundry rooms, and lower levels) plus proper vapor control helps keep moisture where it belongs—and out of your wall cavities.

Flooring options suited for humidity (porcelain, engineered wood, stone)

Porcelain tile, natural stone, and quality engineered hardwoods are generally better fits than traditional solid wood floors in a humid climate, especially near doors and high-traffic outdoor connections.

7. Outdoor Living Materials Designed for the Tropics

Composite decking, tropical hardwoods (ipe, teak)

Outdoor decks and docks made from composite materials or dense tropical hardwoods (properly detailed and maintained) stand up better to sun, rain, and salt.

Corrosion-resistant outdoor cabinets and appliances

Outdoor kitchens should be built with stainless or marine-grade components. Standard indoor-grade hardware and cheap appliances won’t last long in coastal conditions.

UV-stable fabrics and finishes

Outdoor fabrics, cushions, and finishes must resist fading, mildew, and breakdown from UV exposure. Choosing products that are truly rated for the tropics will cut down on how often you replace them.

How High-Performance Materials Reduce Maintenance Costs

Lower Frequency of Repairs & Replacements

Longer lifespan in a corrosive environment

High-performance materials are engineered to last longer in harsh conditions. That means fewer roof repairs, fewer failed windows, and fewer exterior repaint cycles.

Better Protection During Storms

Reduced chance of catastrophic failures

When storms roll through, high-quality roofs, windows, and structural systems reduce the risk of catastrophic damage. Avoiding major failures isn’t just about repair bills—it’s about staying in your home and getting back to normal faster.

Energy Savings & Comfort

Improved insulation, reduced moisture intake

Energy-efficient windows, strong insulation, and tight building envelopes make your home easier to cool and less prone to humidity swings. Over time, that lowers power usage and increases comfort.

Cost Considerations: Are High-Performance Materials Worth It?

Initial Cost vs Long-Term Value

Why premium materials cost more upfront

There’s no sugar-coating it: climate-resistant materials for Palm Beach homes and other coastal areas often cost more at the start. You’re paying for better raw materials, more robust engineering, and stricter testing.

ROI over the home's lifetime (repair, insurance, efficiency)

But look at the full life of the home: fewer repairs, better insurance credits, less frequent replacement, and lower energy bills. Over 10–20 years, those benefits become very real. Many of our clients see it as an “insurance policy” built into the walls and roof.

Insurance Benefits & Risk Reduction

Credits for hurricane-resistant construction

Impact-rated openings, fortified roofs, and strong structural systems often qualify for insurance credits. Your agent can help quantify those savings based on specific upgrades.

Lower long-term premiums

When your home is less likely to suffer major storm damage, insurers see it as a lower risk. That can translate into better premiums over time.

Resale Value & Market Expectations

Luxury buyers demand resilience + low maintenance

In the luxury segment, buyers expect high-performance materials luxury homes South Florida to be standard. They’re looking for homes that show well and live well—without looming maintenance surprises.

Higher appraisal value for storm-ready homes

Appraisers and buyers both recognize the value of hurricane-rated systems, quality roofing, and premium exteriors. A home that “checks the boxes” for coastal durability stands out in a competitive market.

How to Choose the Right Materials

Work With Coastal-Experienced Architects & Builders

Professionals who understand code, engineering, and climate

The best decisions come from a team that lives and breathes this environment. Working with a builder who has deep coastal experience—like our team serving communities featured in Our Service Area—helps ensure your home is designed from day one for South Florida’s realities.

Evaluate Material Performance Ratings

ASTM standards, wind uplift ratings, corrosion resistance

Look beyond brand names and colors. Ask about uplift ratings, impact certifications, salt-spray tests, and independent performance standards. These numbers tell you how materials are likely to behave in real conditions.

Prioritize Systems Over Aesthetics Alone

Select durable structures first, then refine with design

You can always tweak colors and finishes, but the structure, roof system, and windows are much harder to change later. Focus your budget there first, then layer in the fine design details.

Consider HOA & Coastal Building Regulations

Ensure materials meet local restrictions & code requirements

HOAs and coastal jurisdictions sometimes specify or limit certain materials. Your architect and builder should help navigate those requirements to balance aesthetics, performance, and compliance.

Homeowner Checklist: Selecting High-Performance Materials

Confirm wind-load + hurricane-impact ratings

Ask for documentation that your windows, doors, and roof systems meet or exceed local hurricane standards.

Choose corrosion-resistant materials for all exterior elements

From fasteners to railings and outdoor kitchens, insist on materials designed for salt air.

Verify moisture & mold resistance for interior systems

Check that insulation, drywall, and flooring are appropriate for our humidity and won’t become liabilities later.

Evaluate lifecycle cost, not just installation price

Compare upfront cost with expected lifespan, maintenance needs, and performance. Cheaper now can mean more expensive later.

Request manufacturer warranties and maintenance requirements

Good products come with strong warranties and clear care instructions. Use those to plan your long-term maintenance strategy.

FAQs About High-Performance Materials in South Florida

Is wood framing viable in coastal Florida?

It can be, especially when engineered correctly and used with the right protective measures. However, many high-end coastal homes lean toward concrete or hybrid systems for durability and storm performance.

How long do impact windows last?

With proper installation and maintenance, quality impact windows can last decades. Over time, seals and hardware may need attention, but the core laminated glass is designed for longevity.

What roofing materials perform best in hurricanes?

Metal roofing and properly installed concrete tile, combined with sealed roof decks and quality fasteners, are among the top choices for hurricane-prone coastal areas.

Does coastal humidity affect interior finishes?

Yes. Poorly chosen or installed finishes can swell, peel, or support mold growth. High-performance materials and careful climate control help prevent those issues.

Are high-performance materials required by code?

Certain performance levels—for wind, impact, and energy—are required by code, especially near the coast. Going beyond minimums is often where you see the biggest benefits in comfort and reduced maintenance.

Conclusion — Build Smarter for the South Florida Climate

Resilient, high-performance materials protect your investment

When you step back and look at the full picture, it’s clear Why High-Performance Materials Matter in South Florida’s Climate (Wind, Humidity, Salt Air. Your home isn’t just dealing with pretty beach weather; it’s working through some of the toughest residential conditions in the country.

Better comfort, safety, and longevity for coastal living

Choosing the right materials means fewer worries every hurricane season, better day-to-day comfort, and a home that still looks and feels fantastic years down the road. That’s true whether you’re building in Palm Beach, Palm City, West Palm Beach, or other coastal communities we serve—learn more about those areas in Affordable Luxury: Best Home Builders in Palm City and Custom Home Builders in West Palm Beach, FL.

Strategic material choices drastically reduce long-term costs

If you’re planning a new custom build or a major renovation and want to use materials that truly match the environment, start by exploring Our Service Area. Then call 561-962-4567 to talk with the Luxure Group team about your project. We’ll help you apply everything from this guide on Why High-Performance Materials Matter in South Florida’s Climate (Wind, Humidity, Salt Air to your specific site, design, and long-term goals—so your home looks beautiful and stands strong for years to come.